Woodworking Equipment

New products

-

MZB Professional Oilless Air Compressor - 90L, 840L/min, 8 Bar

Professional MZB oilless air compressor with 90L tank delivers 840 L/min...

599,00 € -

GTM MT S 120-3/220V Professional Oil-Free Silent Air Compressor (120L)

Ensure sterile, quiet airflow with the GTM MT S 120-3/220V Oil-Free Air...

599,00 € -

Bertz N2 1.1‑ton mini excavator

Compact 1.1‑ton mini excavator with KOOP 192F EURO 5 diesel engine,...

8 738,89 € -

Bertz N1 Mini Excavator (1.1 Ton) – Euro 5 Diesel

The Bertz N1 is a 1.1-ton mini excavator featuring a robust 7.6 kW Koop...

5 781,10 € -

Rear W7108-8 BMW Satin Black R19-9J 5x120mm 72.56

Rear W7108-8 BMW Satin Black R19-9J 5x120mm 72.56

209,00 € -

Front W7108-7 BMW Satin Black R19-8J 5x120mm 72.56

Front W7108-7 BMW Satin Black R19-8J 5x120mm 72.56

209,00 € -

Rear W7108-6J BMW Satin Black R19-9J 5x112mm 66.5

Rear W7108-6J BMW Satin Black R19-9J 5x112mm 66.5

209,00 € -

Front W7108-5 BMW Stin Black R19-8J 5x112mm 66.5

Front W7108-5 BMW Stin Black R19-8J 5x112mm 66.5

209,00 €

Viewed products

-

MULTI-SAW LANTZMANN...

Ideal multi-saw for obtaining lumber...

-

MULTI-SAW LANTZMANN...

Working thickness: 10 ~ 120 mm Max....

View larger

View larger

MULTI-SAW LANTZMANN MULTICUT 350/170

MULTICUT 350/170

-

Ideal multi-saw for obtaining lumber in companies and shops for the production of lumber, carpentry and construction products, and other woodworking industries.

More info

Advantages:

-

Cast iron chrome feeding table: heat treated for maximum stability. Adjustments to the feed table and fence are quick using the quick adjustment levers

-

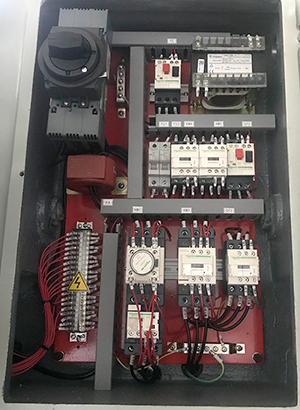

Professional electrical appliances: Siemens and Schneider ensure the good operation and stable performance of the whole machine

-

High precision spindle: spindles are precision engineered and specially heat treated to ensure maximum cutting stability and consistent accuracy

-

Anti-kick safety element: located on the supply ensures safe operation

-

Cast iron frame: Stable, very rigid construction

Technical indicators:

| Max. the thickness of the material to be processed | 10 - 170 mm |

| Max. working width | 350 mm |

| Min. length of material to be processed, at continuous feed | 740 mm |

| Diameter of installed saws | 355 - 505 mm |

| Diameter of "landing" saws | 80 mm |

| Feed rate | 3 - 24 m / min |

| Saw cutting frequency | 2600 rpm |

| Saw spindle drive power | 55 kW |

| Feed drive power | 4 kW |

| Lifting/lowering drive power | 0,75 kW |

| Total power | 59,75 kW |

| Pressure in the pneumatic system | 0,3 - 0,6 MPa |

| Pipe diameter for aspiration | 2 x 150 mm |

| Length | 2100 mm |

| Width | 1950 mm |

| Height | 2100 mm |

| Weight net | 3500 kg |

.png) |

Solid cast iron bed A solid cast iron bed subjected to a special heat treatment followed by machining in a CNC machining center in one installation. Provides maximum stability and reliability, completely eliminates the possibility of vibration. |

|

|

Saw shaft The console-type saw spindle allows processing of workpieces of increased width and greatly facilitates the change of saws. In addition, this design allows you to adjust the saw shaft vertically to use saws of different diameters from 355 to 505 mm, depending on the thickness of the workpiece. |

|

|

Supply system The billet feeding system is made on the basis of a caterpillar conveyor with an increased section, the conveyor elements are made with appropriate further heat treatment. The track system ensures a smooth and stable feed of the workpiece during processing, which ensures high-quality cuts. |

|

|

Conveyor cleaning and lubrication The crawler conveyor is equipped with brushes and an automatic pump for supplying lubricant to the rear of the conveyor, which greatly increases the life of the conveyor and equipment. |

|

|

Nail protection Double (one at the bottom and one at the top) claw curtain for the protection of the operator, made in accordance with the norms of safety regulations for woodworking equipment. |

|

Pressure roller height adjustment The electromechanical lifting and lowering of the traverse with the base rollers ensures the accuracy and speed of the height adjustment of the spring rollers. |

|

Saw spindle drive The saw shaft is driven by a 55 kW electric motor through 8 V-belts. This belt drive provides stable torque transmission. |

|

Control Panel The ergonomic control panel is designed according to global trends in the machine tool industry to ensure maximum protection and ease of use of the machine. The feed speed of the workpiece is controlled by the inverter and set on the control panel. |

|

Electrical cabinet The electrical cabinet is equipped with Schneider and Siemens Sirius components. Manufactured according to CE standards. |